Bioprocess monitoring.

Applications

Synthetic

biology.

IS ABOUT TO CHANGE THE WORLD

The impact of waveguide-enhanced Raman on bioprocess monitoring.

The implementation of Process Analytical Technologies (PATs), recommended by regulatory agencies for over 20 years, has revolutionized the bioprocessing industry by significantly improving process efficiency, product quality, and regulatory compliance. Among the various PAT techniques, Raman spectroscopy stands out as a particularly powerful tool. Raman spectroscopy’s in-line and real-time monitoring capabilities have brought about transformative changes in bioprocessing by enabling precise control and optimization of critical parameters throughout the entire production cycle. Its ability to offer detailed chemical information has led to enhanced process understanding, facilitating data-driven decisions and yielding numerous advantages in terms of both operational efficiency and product quality.

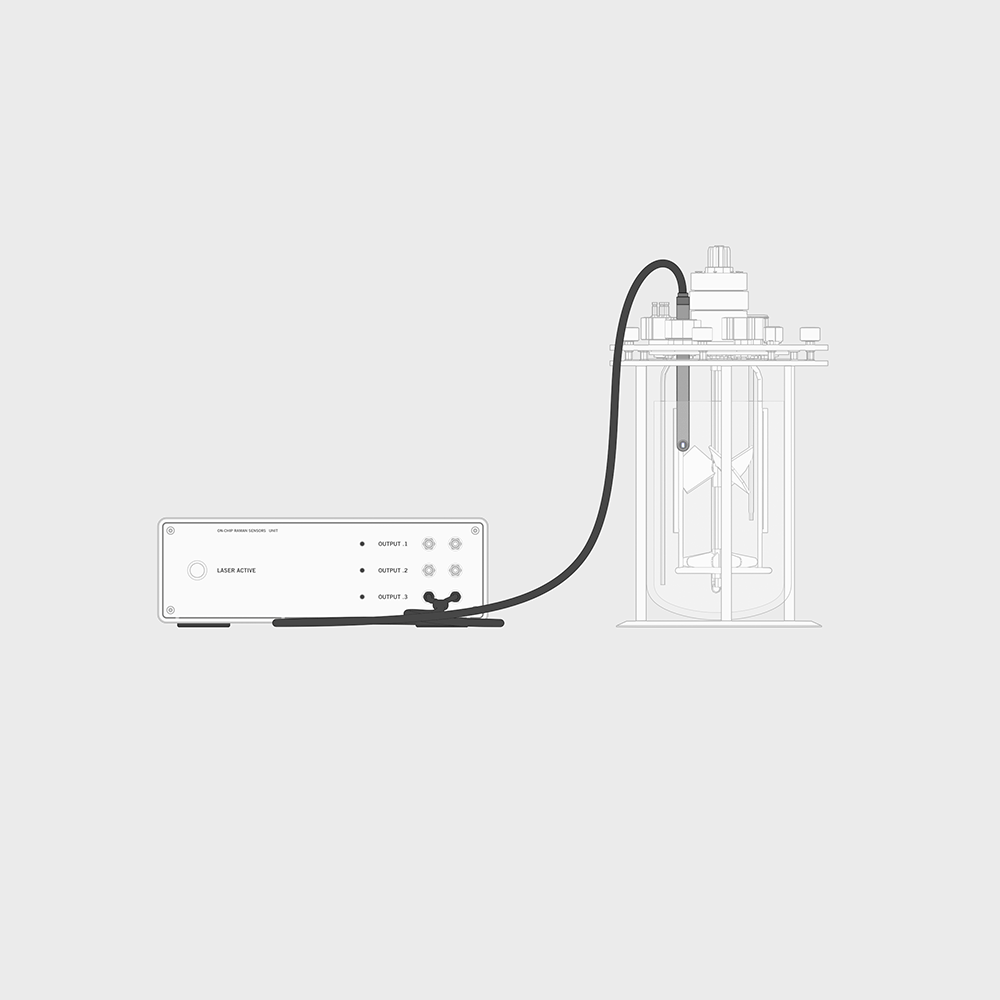

In the field of bioprocesses and biotechnology, where precision and efficiency are paramount, our cutting-edge sensor technology revolutionizes the landscape. Our sensors, based on waveguide-enhanced Raman spectroscopy (WERS), bring a new era of real-time, non-invasive analysis to bioreactors and flow systems of all scales. Whether you’re operating with single-use technologies or traditional setups, our compact and versatile sensors provide a comprehensive view of your bioprocesses, optimizing yield, minimizing waste, and accelerating development. In the pursuit of sustainable and high-quality bioproduction, our technology is your guiding light.

Applications

in your industry.

Benefits

for bioprocessing.

Cost and single-use compatibility

By reducing the cost of probes, Raman spectroscopy can be applied as a new solution for single-use technologies. Open to wider cost-efficient options, several probes can be connected to a single control unit.

Optimize yields and product quality

By monitoring both qualitative and quantitative specific data from your process, real time information becomes accessible.

Sensing area

The sensing area of our sensors, where the light interacts with the medium, is only a few (<5) mm². This means that very small volumes are enough to make a measurement.

Sensitivity and selectivity for all molecules

By optimizing the light-sample interaction, we ensure optimal sensitivity and selectivity. As our technology is based on molecular vibrations, we can detect a large panel of information within the same measurement.

Sample preparation and measurement time

No preparation needed, only a few seconds are required to obtain your data.

Sterilisation

Material made of USP class VI, all classic industrial sterilisation are covered.

Compatible with all sterilisation methods.