The impact of waveguide-enhanced Raman on reaction monitoring.

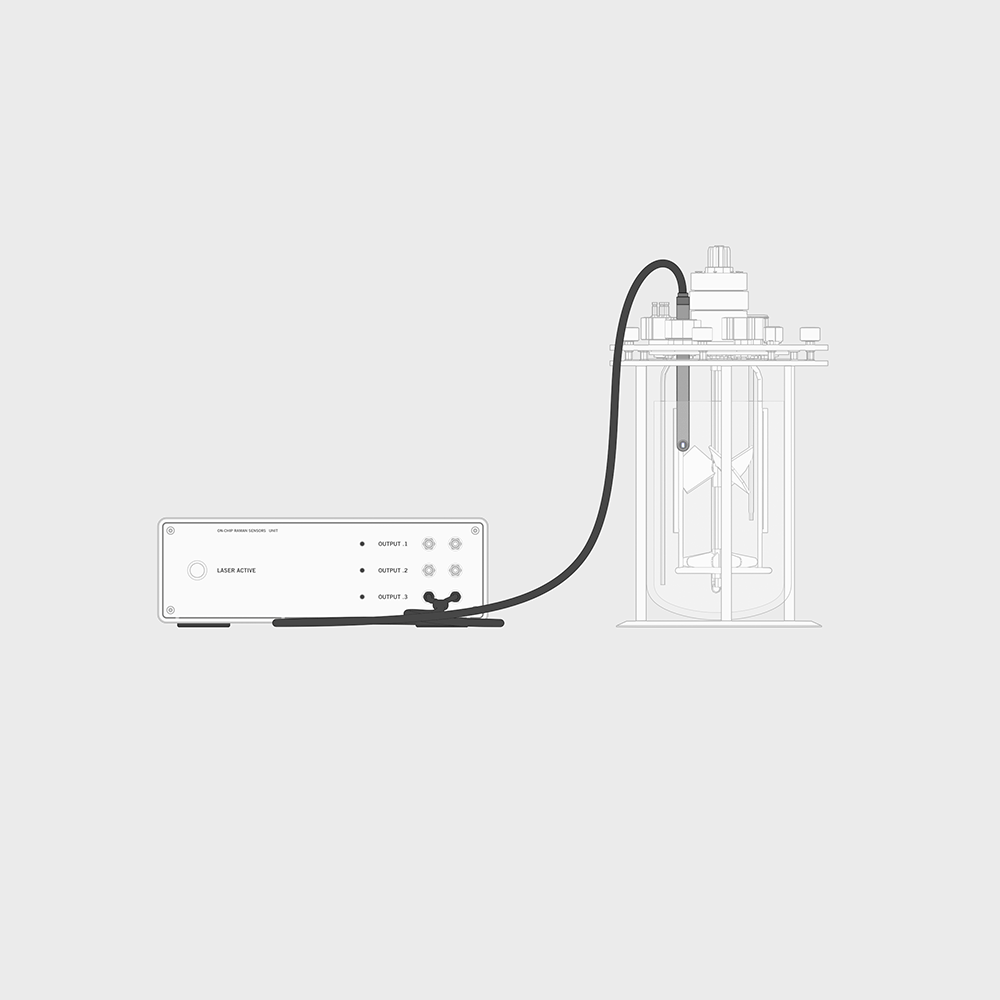

In the realm of chemical reactions, precision and control are the cornerstones of success. Our state-of-the-art sensor technology, based on waveguide-enhanced Raman spectroscopy (WERS), empowers industries to gain unparalleled insights into chemical systems. Real-time composition analysis, whether in batch processes or continuous flow, has never been more accessible, even for small volumes. By harnessing the unique advantages of our integrated photonics-on-a-chip approach, we offer precise, cost-effective, and non-invasive monitoring solutions. With our sensors, industries can achieve real-time control, reduce operational costs, and ensure product quality with unprecedented confidence. Welcome to the future of chemical reaction monitoring.