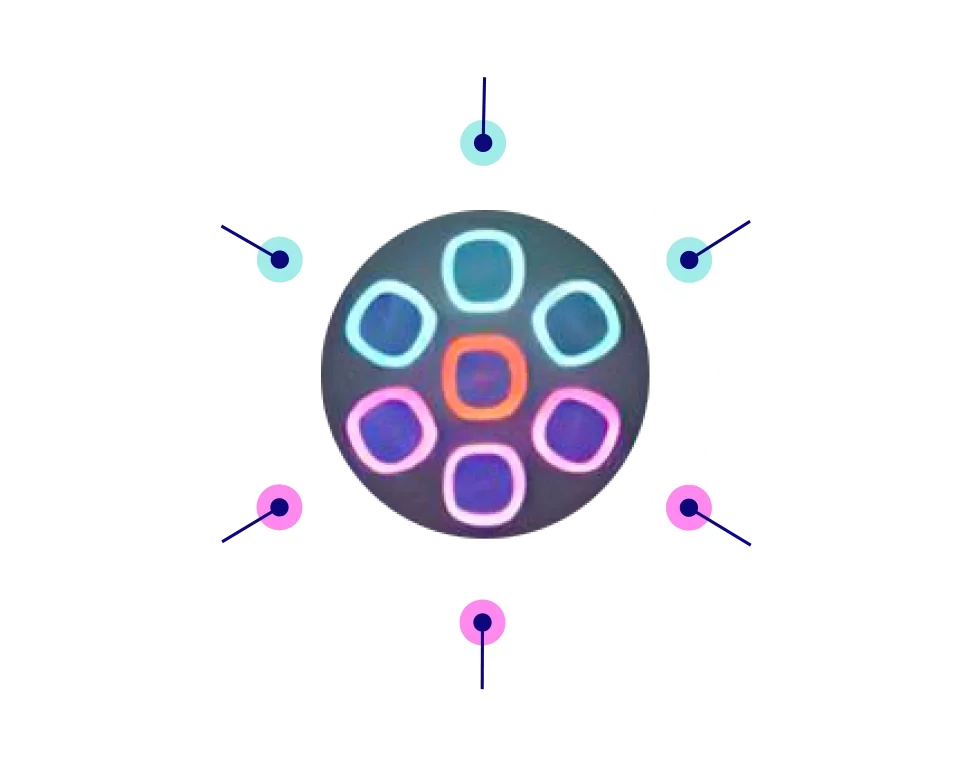

Optics is a cornerstone technology in sensing applications due to its ability to capture and analyze complex data through the properties of light. The wealth of information carried by light allows for versatile, sensitive detection of a wide range of substances and phenomena in complex samples such as multi-component mixtures or intricate material structures. Its non-invasiveness enables measurements without altering the target. Overall, the precision, non-destructive nature, and data-rich output of optics make it an indispensable tool for advancing sensing capabilities across various industries.

Optical sensing,

on a chip.

Optics

Chip integration

Integrated photonics, or the integration of optical systems on semiconductor chips, builds off the successes of the electronics industry over the last decades. The ability to design and manufacture chips that guide and manipulate light provides optical devices with the same advantages as electronic chips: the miniaturization of complex systems reduces the size, weight, and cost of devices while enhancing their performance. As photonic integrated circuits (PICs) can now be mass-produced with high precision and efficiency, photonic integration has become an indispensable technology with ever-increasing maturity and capabilities.